Spindle Learning Control Manual Additional Manual Page 21

Additional Manual

21/22

Design.

DateEd.

2002.05.06

SHEET

DRAW. No.

CUST.

TITLE

M.Niwa

Newly preparation

Spindle Learning Control Description

A-53866E-0425

FANUC LTD

01

speed

command

(min

-1

)

actual

speed

command

(min

-1

)

learnin

g

period

(0.5ms)

speed

command

(min

-1

)

actual

speed

command

(min

-1

)

learnin

g

period

(0.5ms)

speed

command

(min

-1

)

actual

speed

command

(min

-1

)

learnin

g

period

(0.5ms)

speed

command

(min

-1

)

actual

speed

command

(min

-1

)

learnin

g

period

(0.5ms)

265 264.90 453 325 324.32 370 390 389.61 308 484~485 483.87 248

266 265.49 452 326 325.20 369 391~392 390.88 307 486~487 485.83 247

267 266.67 450 327 326.98 367 393 392.16 306 488~489 487.80 246

268 267.86 448 328 327.87 366 394 393.44 305 490~491 489.80 245

269 268.46 447 329 328.77 365 395~396 394.74 304 492~493 491.80 244

270 269.66 445 330 329.67 364 397 396.04 303 494~495 493.83 243

271 270.88 443 331 330.58 363 398 397.35 302 496~497 495.87 242

272 271.49 442 332 331.49 362 399 398.67 301 498~499 497.93 241

273 272.73 440 333 332.41 361 400~401 400.00 300 500~502 500.00 240

274 273.97 438 334 333.33 360 402 401.34 299 503~504 502.09 239

275 274.60 437 335 334.26 359 403~404 402.68 298 505~506 504.20 238

276 275.86 435 336 335.20 358 405 404.04 297 507~508 506.33 237

277 276.50 434 337 336.13 357 406 405.41 296 509~510 508.47 236

278 277.78 432 338 337.08 356 407~408 406.78 295 511~512 510.64 235

279 278.42 431 339 338.98 354 409 408.16 294 513~515 512.82 234

280 279.72 429 340 339.94 353 410 409.56 293 516~517 515.02 233

281 280.37 428 341 340.91 352 411~412 410.96 292 518~519 517.24 232

282 281.69 426 342 341.88 351 413 412.37 291 520~521 519.48 231

283 282.35 425 343 342.86 350 414~415 413.79 290 522~524 521.74 230

284 283.69 423 344 343.84 349 416 415.22 289 525~526 524.02 229

285 284.36 422 345 344.83 348 417~418 416.67 288 527~528 526.32 228

286 285.71 420 346 345.82 347 419 418.12 287 529~530 528.63 227

287 286.40 419 347 346.82 346 420~421 419.58 286 531~533 530.97 226

288 287.77 417 348 347.83 345 422 421.05 285 534~535 533.33 225

289 288.46 416 349 348.84 344 423~424 422.54 284 536~538 535.71 224

290 289.86 414 350 349.85 343 425 424.03 283 539~540 538.12 223

291 290.56 413 351 350.88 342 426~427 425.53 282 541~542 540.54 222

292 291.97 411 352 351.91 341 428 427.05 281 543~545 542.99 221

293 292.68 410 353 352.94 340 429~430 428.57 280 546~547 545.45 220

294 293.40 409 354~355 353.98 339 431 430.11 279 548~550 547.95 219

295 294.84 407 356 355.03 338 432~433 431.65 278 551~552 550.46 218

296 295.57 406 357 356.08 337 434 433.21 277 553~555 553.00 217

297 296.30 405 358 357.14 336 435~436 434.78 276 556~558 555.56 216

298 297.77 403 359 358.21 335 437 436.36 275 559~560 558.14 215

299 298.51 402 360 359.28 334 438~439 437.96 274 561~563 560.75 214

300 300.00 400 361 360.36 333 440~441 439.56 273 564~566 563.38 213

301 300.75 399 362 361.45 332 442 441.18 272 567~568 566.04 212

302 301.51 398 363 362.54 331 443~444 442.80 271 569~571 568.72 211

303 302.27 397 364 363.64 330 445~446 444.44 270 572~574 571.43 210

304 303.80 395 365 364.74 329 447 446.10 269 575~576 574.16 209

305 304.57 394 366 365.85 328 448~449 447.76 268 577~579 576.92 208

306 305.34 393 367~368 366.97 327 450~451 449.44 267 580~582 579.71 207

307 306.91 391 369 368.10 326 452 451.13 266 583~585 582.52 206

308 307.69 390 370 369.23 325 453~454 452.83 265 586~588 585.37 205

309 308.48 389 371 370.37 324 455~456 454.55 264 589~591 588.24 204

310 309.28 388 372 371.52 323 457~458 456.27 263 592~594 591.13 203

311 310.88 386 373 372.67 322 459 458.02 262 595~597 594.06 202

312 311.69 385 374 373.83 321 460~461 459.77 261 598~599 597.01 201

313 312.50 384 375~376 375.00 320 462~463 461.54 260 600~603 600.00 200

314 313.32 383 377 376.18 319 464~465 463.32 259 604~606 603.02 199

315 314.96 381 378 377.36 318 466 465.12 258 607~609 606.06 198

316 315.79 380 379 378.55 317 467~468 466.93 257 610~612 609.14 197

317 316.62 379 380 379.75 316 469~470 468.75 256 613~615 612.24 196

318 317.46 378 381~382 380.95 315 471~472 470.59 255 616~618 615.38 195

319 318.30 377 383 382.17 314 473~474 472.44 254 619~621 618.56 194

320 320.00 375 384 383.39 313 475~476 474.31 253 622~624 621.76 193

321 320.86 374 385 384.62 312 477~478 476.19 252 625~628 625.00 192

322 321.72 373 386~387 385.85 311 479 478.09 251 629~631 628.27 191

323 322.58 372 388 387.10 310 480~481 480.00 250 632~634 631.58 190

324 323.45 371 389 388.35 309 482~483 481.93 249 635~638 634.92 189

Contents Summary of Spindle Learning Control Manual Additional Manual

- Page 1FANUC AC SPINDLE MOTOR αi series Spindle Learning Control Description 1. General ................................................................................................................................................. 2 1.1. Overview..........................................................

- Page 21. General 1.1. Overview This manual describes methods for applying Spindle Learning Control for reducing periodic synchronous error between master and slave axes in gear cutting process. See “90A3 / 90A7 / 90B3 / 90B7 Learning Control Operator’s Manual : A-63696E-070” for detailed explanation of Le

- Page 32.1.2. Example 1 : in case of direct drive system velocity and position sensor Built-in spindle motor CNC 1st spindle (master axis) Series 16i/160i/160is JA7B JYA2 18i/180i/180is MODEL B SPM TYPE B JA7A JX4 velocity and position sensor communication between SPMs Built-in spindle motor JX4 JA7B JYA2

- Page 42.1.3. Example 2 : in case of full-closed system with gear reduction velocity sensor Spindle motor CNC 1st spindle (master axis) Series 16i/160i/160is Spindle JA7B JYA2 18i/180i/180is shaft MODEL B SPM external TYPE B position sensor JA7A JYA4 JX4 velocity sensor communication between SPMs Spindle m

- Page 52.1.4. Example 3 : In case of semi-closed system with gear reduction velocity and position sensor Spindle motor CNC 1st spindle (master axis) Series 16i/160i/160is Spindle JA7B JYA2 18i/180i/180is external shaft MODEL B SPM one-rotation TYPE B signal (proximity switch) JA7A JYA3 JX4 velocity and pos

- Page 62.2. Software configuration 2.2.1. Spindle software Software series / edition note Series 9D50 edition E(05) or later for induction motor control Series 9D53 edition B(02) or later for synchronous motor control 2.2.2. CNC software Software series / edition note Series B0H1 edition R(18) or later for

- Page 73. Block diagram CNC 2nd Spindle position feedback velocity feedback - - Slave Helical + + position + velocity spindle movement controller controller & command ( Gain Kp2 ) + + + Sensor No.4069~4072 Learning Learning period controller Feedforward (coefficient α2) No.4036 K2 Synchronous ratio K1 No.4

- Page 84. Input / Output Signals (CNC ↔ PMC) 4.1. Input signal (PMC → CNC) address #7 #6 #5 #4 #3 #2 #1 #0 G073 LCMODA G077 LCMODB LCMODA : Learning Control request signal (for 1st spindle) LCMODB : Learning Control request signal (for 2nd spindle) 0 : Disables Learning Control 1 : Enables Learning Control

- Page 95. Example of sequence master : 1st spindle, master axis of Spindle EGB control master axis speed command slave : 2nd spindle, slave axis of Spindle EGB control slave axis speed command synchoronization synchoronization start by G81 finish by G80 SYNMOD (F65#6) LCVARA (F48#5) LCMODA (G73#6) LCMODB (

- Page 106. Parameters 6.1. Parameters related to sensors *See “FANUC AC SPINDLE MOTOR αi series PARAMETER MANUAL : B-65280EN” for more information about sensor settings. Parameter No. 4000 ROTA1 #7 #6 #5 #4 #3 #2 #1 #0 ROTA1 : Relationship between the rotation direction of spindle and spindle motor. Paramet

- Page 11Parameter No. 4056 Gear ratio (HIGH) CTH1A=0, CTH2A=0 4057 Gear ratio (MEDIUM HIGH) CTH1A=0, CTH2A=1 4058 Gear ratio (MEDIUM LOW) CTH1A=1, CTH2A=0 4059 Gear ratio (LOW) CTH1A=1, CTH2A=1 data unit : Motor rotation for one rotation of spindle × 100 (In case of No.4006#1=1, motor rotation × 1000) data

- Page 126.2. Parameters related to position loop control for constant velocity command in PMC axis control *Master axis (1st spindle) must be driven by this function in Cs contouring mode when Spindle Learning Control function is used. *See “FANUC Series 16i / 18i SPECIFICATIONS FOR POSITION LOOP CONTROL FO

- Page 136.3. Parameters related to Spindle EGB control function *See “FANUC Series 16i / 18i -MA Spindle electronic gear box Specifications : A-77833E” for more information about Spindle EGB Control. *CNC software option is required to use Spindle EGB Control function 6.3.1. Parameters related to serial spi

- Page 14Parameter No. 4386 Gear teeth number of spindle sensor of master axis data unit : 1λ / rev data range : 0, 64 ~ 4096 This data is used to set the gear teeth number of spindle sensor of master axis. When this parameter is set to “0”, synchronous ratio “0” is assumed. *This parameter is valid only for

- Page 156.3.2. Parameters related to synchronous control Parameter No. 7700 HDR HBR #7 #6 #5 #4 #3 #2 #1 #0 HDR : Setting of the synchronization cancellation by reset HBR : Setting of the direction for helical gear compensation Parameter No. 7703 LFS #7 #6 #5 #4 #3 #2 #1 #0 LFS : Setting of the position com

- Page 166.4. Parameters related to Spindle Learning Control Parameter No. 4015 LRNFNC #7 #6 #5 #4 #3 #2 #1 #0 LRNFNC : Function bit of Learning Control 0 : Learning Control is invalid 1 : Learning Control is valid *CNC software option is required to use this function. This bit is automatically set by CNC so

- Page 17Parameter No. 4431 Duration of learning : LCTIME data unit : 0.1sec data range : 0 ~ 32767 This data is used to set duration of Learning Control. Learning controller stops update of compensation data after the expiration of the time interval that this parameter specifies (See following figure). If “

- Page 187. Diagnosis related to Spindle EGB Control Address Description Unit 716 Synchronous error between master and slave axis in Spindle pulse EGB Control (weight of error is slave axis side) *Both αi SPM TYPE B and i series model B CNC are required for the display of synchronous error on CNC diagnosis s

- Page 199. Tuning of Learning Controller Normally, only tuning of maximum and minimum order of dynamic characteristic compensation Gx (No.4427, 4428) is required. 9.1. Procedure of Leaning Controller tuning Step A Before tuning of Leaning Controller, tune current loop (in case of 3rd party spindle motor), v

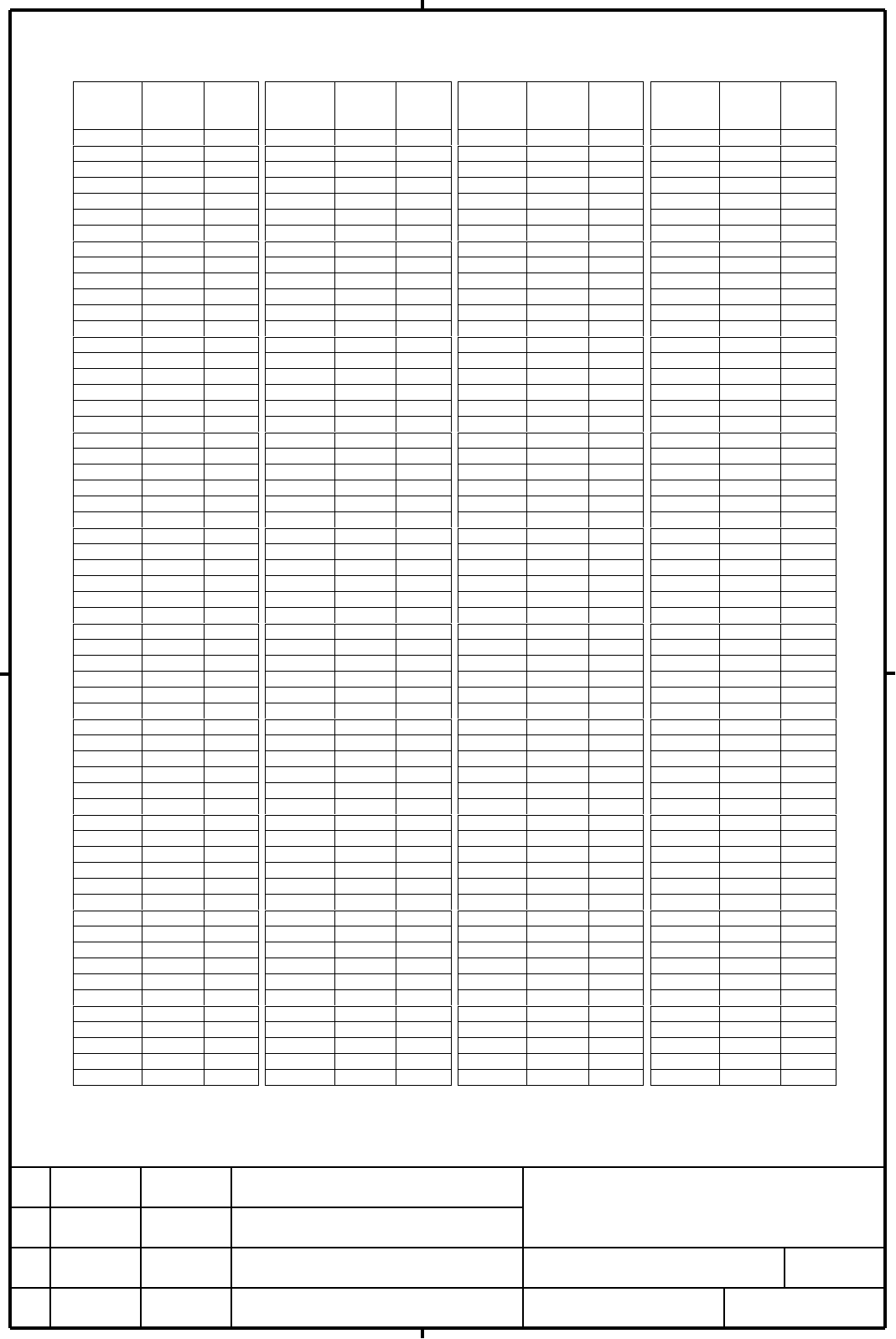

- Page 20Appendix : Relationship between speed command specified by PMC and actual command actual learning Actual learning actual learning actual learning speed speed speed speed speed speed speed speed command period command period command period command period command command command command (min-1) (0.5ms

- Page 21actual actual actual actual speed learning speed learning speed learning speed learning speed speed speed speed command period command period command period command period command command command command (min-1) (0.5ms) (min-1) (0.5ms) (min-1) (0.5ms) (min-1) (0.5ms) (min-1) (min-1) (min-1) (min-1)

- Page 22actual actual actual speed learning speed learning speed learning speed speed speed command period command period command period command command command (min-1) (0.5ms) (min-1) (0.5ms) (min-1) (0.5ms) (min-1) (min-1) (min-1) 639~641 638.30 188 938~944 937.50 128 1765~1791 1764.71 68 642~645 641.71 1